PCB Design & Analysis

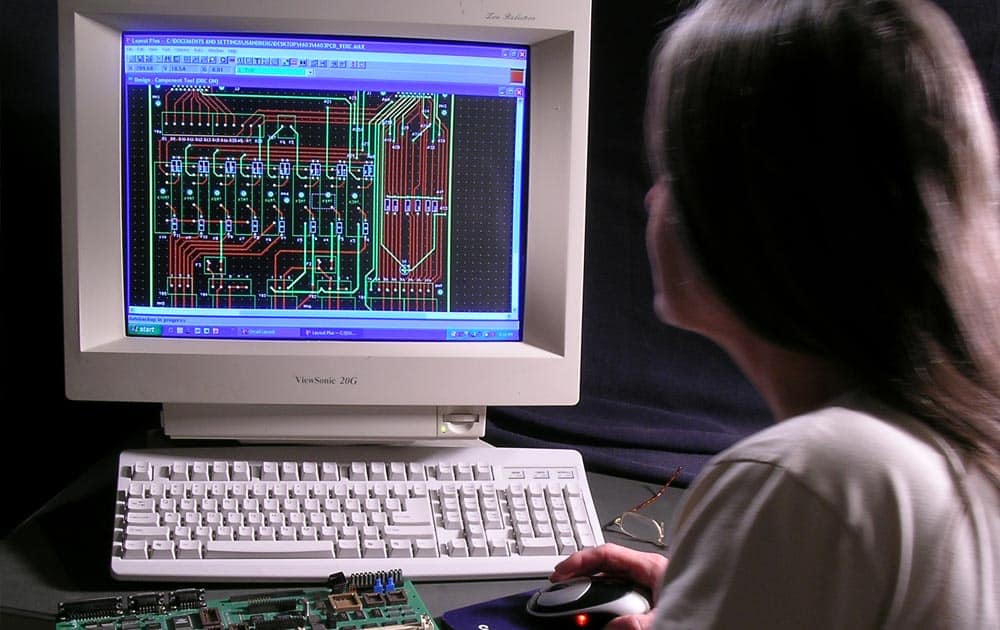

When it comes to PCB design, Layout and Analysis, our design partners measure success one project at a time, actively partnering with every customer to ensure project goals are achieved in the most efficient and cost-effective manner possible.

Design

The paramount aim of our design partners is to meet and exceed the goals of the customer and improve the quality of the circuit assembly. Customers can choose from a variety of services to enhance the project cost-effectiveness and reliability of the circuit assembly. Some of the services that our design partners offer include:

- Schematic Analysis

- Bill of Material review

- Layout and packaging technology review

- Surface Mount

- Through-Hole

- Component Obsolescence and lead time mitigation

- Design for manufacturability review

- Design layout of an electrical circuit

- Electrical and environmental test procedure design and implementation

- Troubleshooting analysis

- Cost reduction analysis

Which technology is right for you?

Use the comparison chart.

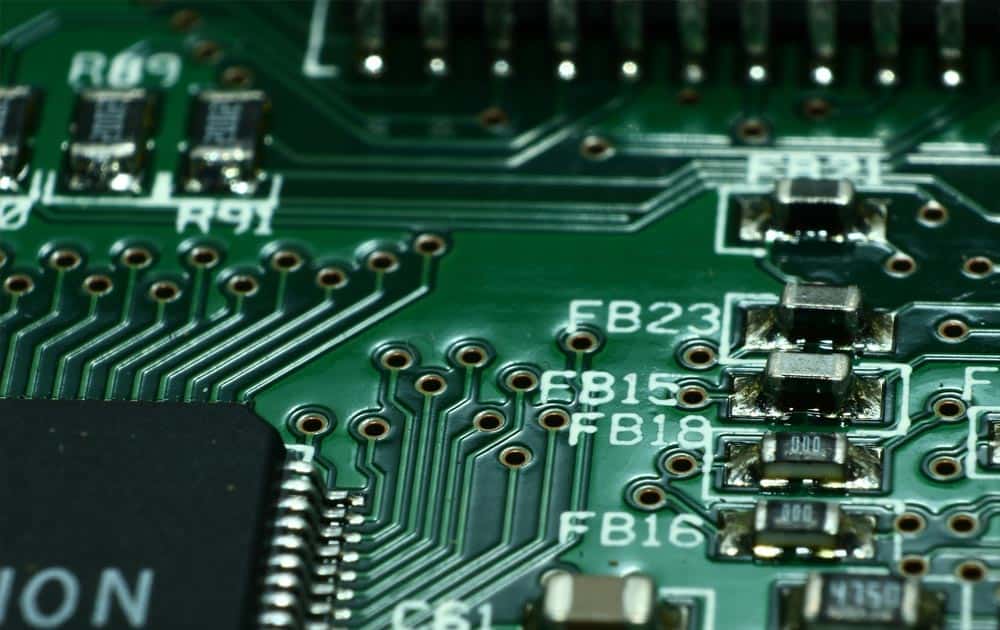

SURFACE MOUNT

SURFACE MOUNT

SMT provides excellent space utilization and a very high degree of circuit reliability.

- LEARN MORE

THROUGH-HOLE PCB

THROUGH-HOLE PCB

Our through-hole PCB assembly procedure can handle both leaded and lead-free (RoHs) applications.

- LEARN MORE

HYBRID THICK FILM

HYBRID THICK FILM

A Hybrid circuit performs all or part of an electronic function by combining and interconnecting...

- LEARN MORE

CHIP ON-BOARD

CHIP ON-BOARD

When design parameters cannot be met by traditional assembly techniques, Chip-On-Board (COB)...

- LEARN MORE

MULTI-CHIP MODULE

MULTI-CHIP MODULE

MCM has the same basic construction as Chip-On-Board but with some significant differences.

- LEARN MORE

BOX BUILD ASSEMBLY

BOX BUILD ASSEMBLY

Box build assembly consists of all the remaining assembly processes required to integrate...

- LEARN MORE

LINKS

CONTACT US

103 Grant Street

Aurora, NE 68818

Phone: 402-694-6111

Toll-Free: 800-260-6287

Fax: 402-694-6180