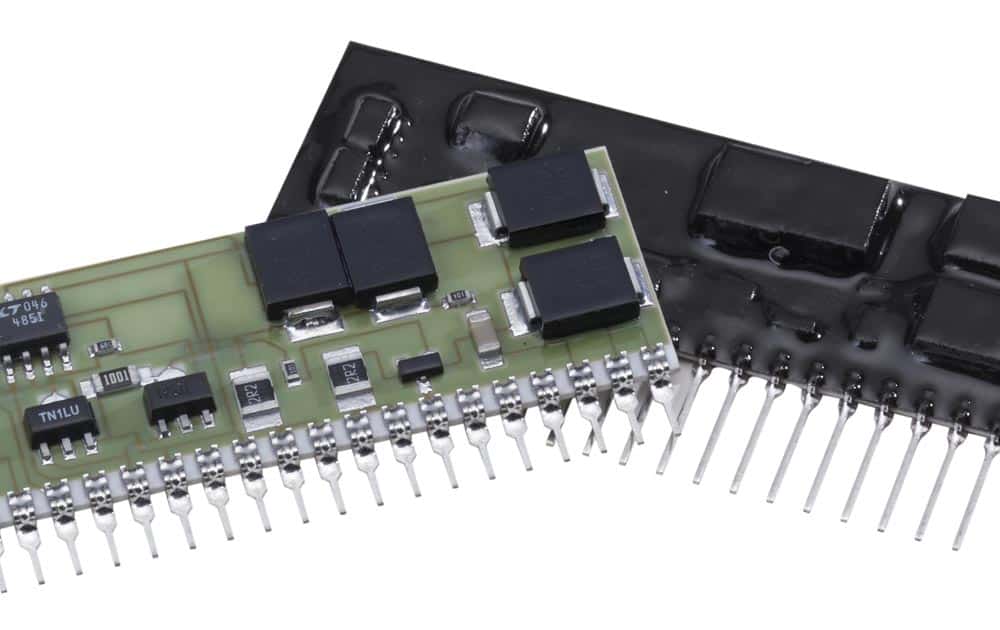

Hybrid Circuits – Thick Film Assembly

There are a variety of options for base materials of thick film substrates depending on the customer’s specific needs, such as Alumina (AL203), Aluminum nitride (AIN) or Beryllia (BeO). The selected substrate will be screen-printed with the conductor pattern and thick film resistors. Screen-printed resistors provide numerous benefits, including better tracking, improved interconnect reliability and package design flexibility through size reduction. The printed paste is then fired in tightly monitored temperature controlled, multi-zoned furnaces, binding the paste to the base material and becoming an integral part of the hybrid circuit. Passive and active semiconductor packages are then re-flowed onto the printed substrate. Bare die are attached to the substrate with epoxy and interconnected with gold wire bonds. A variety of lids or coatings may be applied to protect the die and wire bonds.

Ceramic, metal, or plastic covers with adhesive seals

Circuit sealing using junction coating, lids, and other conventional coating materials

Hermetic and non-hermetic packages

Further space savings over surface mount technology

Alumina (AL203), Aluminum Nitride (AIN), and Beryllia (BeO) base materials for excellent heat dissipation

Superior base material power dissipation – Alumina (AL203) high level - 1 Watt per inch per degree C, Aluminum Nitrate (AIN) high level - 7 watts per inch per degree C

Very compact with low profile and low mass

Provides reliable performance in extreme temperature operating ranges

Improved signal-to-noise ratio laminate technologies

Printed thick film resistors trimmed to exacting values

Power rating range one-sixteenth (1/16) to five (5) Watts

Precision Resistors to one-tenth of one percent (0.1%)

Ration matching to one-tenth of one percent (0.1%)

Epoxy and eutectic semi-conductor die attach

Gold thermosonic wire bonding with wire diameters from .0007 to .003 inch.

Re-flow soldering passive component attachment

Wide selection of solder paste and thick film inks available

Functional modularity

Assembled, inspected, and tested to MIL-STD and IPC specifications

A full range of electrical and environmental testing available

Temperature Coefficient Resistance (TCR) as low as 50 ppm with tracking TCR’s to 20 ppm

Which technology is right for you?

Use the comparison chart.

SURFACE MOUNT

SURFACE MOUNT

SMT provides excellent space utilization and a very high degree of circuit reliability.

- LEARN MORE

THROUGH-HOLE PCB

THROUGH-HOLE PCB

Our through-hole PCB assembly procedure can handle both leaded and lead-free (RoHs) applications.

- LEARN MORE

HYBRID THICK FILM

HYBRID THICK FILM

A Hybrid circuit performs all or part of an electronic function by combining and interconnecting...

- LEARN MORE

CHIP ON-BOARD

CHIP ON-BOARD

When design parameters cannot be met by traditional assembly techniques, Chip-On-Board (COB)...

- LEARN MORE

MULTI-CHIP MODULE

MULTI-CHIP MODULE

MCM has the same basic construction as Chip-On-Board but with some significant differences.

- LEARN MORE

BOX BUILD ASSEMBLY

BOX BUILD ASSEMBLY

Box build assembly consists of all the remaining assembly processes required to integrate...

- LEARN MORE

LINKS

CONTACT US

103 Grant Street

Aurora, NE 68818

Phone: 402-694-6111

Toll-Free: 800-260-6287

Fax: 402-694-6180