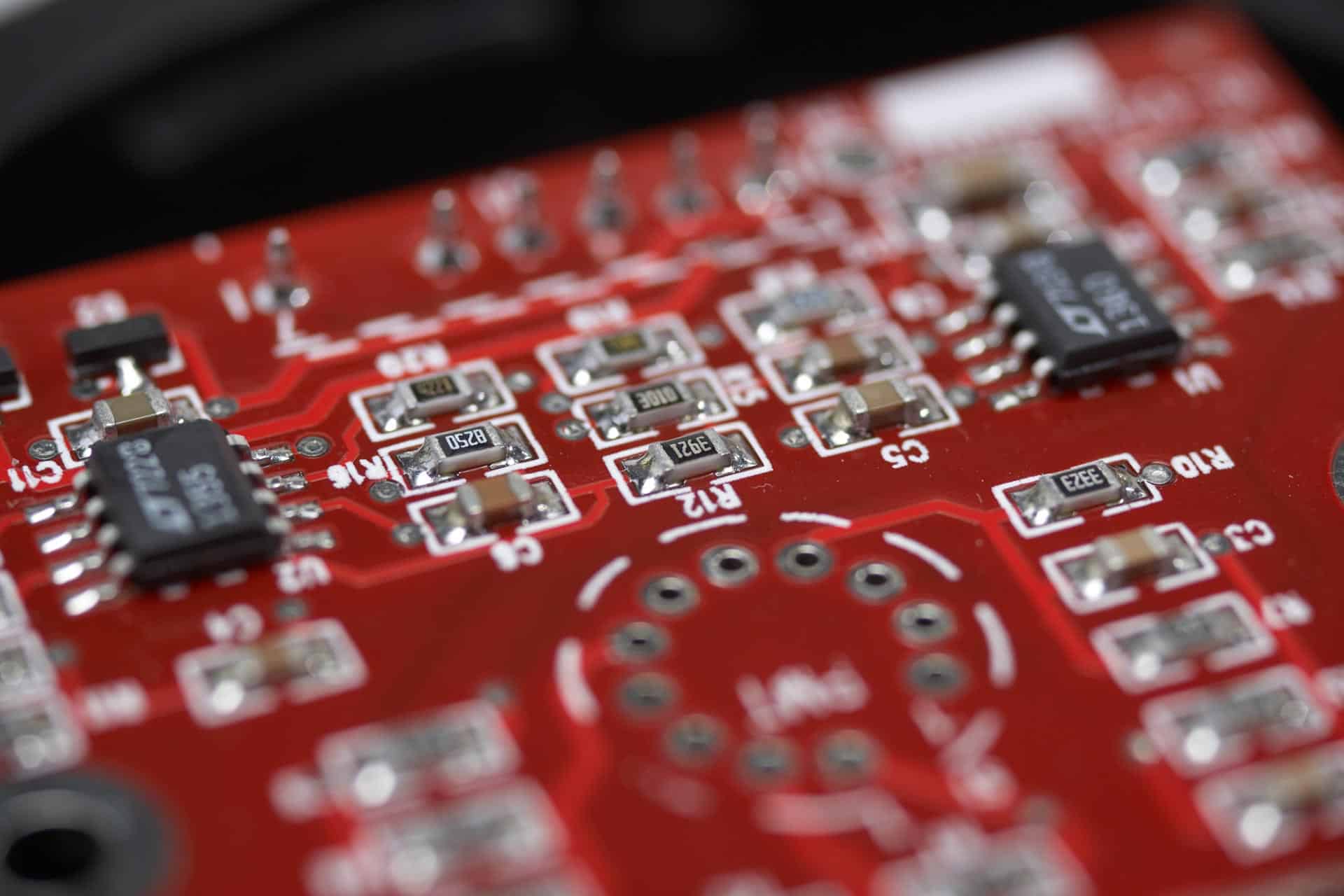

Surface Mount Technology

Surface Mount Technology provides excellent space utilization, and a very high degree of circuit reliability. Surface Mount Technology remains one of the most economical technologies for many applications.

Automatic surface mount assembly capabilities for accurate placement

Fine pitch and BGA placement capabilities

Wide range of base materials available including glass epoxy, ceramic, alumina (96% AL2O3), Aluminum nitrate (AIN), and flex

Single or double-sided assemblies

Full turn key available

Selection of conformal coatings available

Full layout and design capabilities to customer’s print

Manufacturing capabilities from prototype quantities through production volume

Assembled, inspected, and tested to MIL-STD and IPC specifications

Electrical and environmental testing available

RoHs assembly available

Which technology is right for you?

Use the comparison chart.

What is Surface Mount Technology?

In essence, SMT refers to the approach of mounting electrical components directly onto a printed circuit board’s surface. Electrical components that apply this mounting approach are known as surface-mount devices. SMT results from rapid developments in semiconductor manufacturing, which have provided small outline packages for vast components. First, the solder paste is screen printed on the printed circuit board, and then automatic placement tools are used to reposition the components. Next, we solder the reflow to the substrate. While both through-hole and SMT styles are commonly used, and neither seems to go away anytime soon, SMT is the advanced, more compact mounting style of the two. SMT is ideal if you want to optimize your space utilization as it provides a higher level of circuit reliability. It ranks high among the most economical tech approaches for vast applications. It’s applied in vast electronic product varieties, from smartphones and USB flash drives to portable navigation systems and medical devices.

Benefits of Surface Mount Technology

Virtually all commercially manufactured equipment today uses surface-mount technology for its many advantages during PCB manufacturing. More and more PCB devices are available as SMDs or packages, making SMT convenient and cost-effective.

Virtually every commercially manufactured electrical equipment uses surface mount technology. The approach offers many benefits during PCB manufacturing, and you can choose from a wide selection of packages or SMDs. As a result, SMT adoption can be extremely cost-effective and practical.

The primary benefits of surface mount technology include:

- Automated assembly – Automated pick and place tools can easily install most SMT parts. High volume parts, like passive elements, are loaded into the equipment from reels, while the other components come from trays or tube feeders. This is a vital benefit over PTH assembly that uses manual processes.

- Size – Surface mount technology components are relatively smaller. The PCB designer isn’t required to insert, and solder long leads into holes. So they can fit more elements on smaller board space.

- Availability of parts – SMP components are typically the cheaper alternative, thanks to their volume and size. The surge in popularity and demand also means that these solutions are readily available, and you have vast options.

- Electrical performance – Since more small-sized elements are fitted on a single board, you’ll have shorter signal paths. This can substantially improve the signal board integrity and generate less heat.

Upgrade Your Old Technology

The primary reason that through-hole PCBs are still being produced is that many companies are still working with older designs. This can typically be done so long as you aren’t running into major component obsolescence issues. However, there are usually significant cost reductions and quality improvement opportunities to update your through-hole design to an SMT design. You can count on Aurora Boardworks for the latest SMT solutions, and we can help you with design updates. Our efficient approach involves using advanced surface mount placement tools and qualified staff with the flexibility to assemble excellent SMT circuits.

SURFACE MOUNT

SURFACE MOUNT

SMT provides excellent space utilization and a very high degree of circuit reliability.

- LEARN MORE

THROUGH-HOLE PCB

THROUGH-HOLE PCB

Our through-hole PCB assembly procedure can handle both leaded and lead-free (RoHs) applications.

- LEARN MORE

HYBRID THICK FILM

HYBRID THICK FILM

A Hybrid circuit performs all or part of an electronic function by combining and interconnecting...

- LEARN MORE

CHIP ON-BOARD

CHIP ON-BOARD

When design parameters cannot be met by traditional assembly techniques, Chip-On-Board (COB)...

- LEARN MORE

MULTI-CHIP MODULE

MULTI-CHIP MODULE

MCM has the same basic construction as Chip-On-Board but with some significant differences.

- LEARN MORE

BOX BUILD ASSEMBLY

BOX BUILD ASSEMBLY

Box build assembly consists of all the remaining assembly processes required to integrate...

- LEARN MORE

LINKS

CONTACT US

103 Grant Street

Aurora, NE 68818

Phone: 402-694-6111

Toll-Free: 800-260-6287

Fax: 402-694-6180