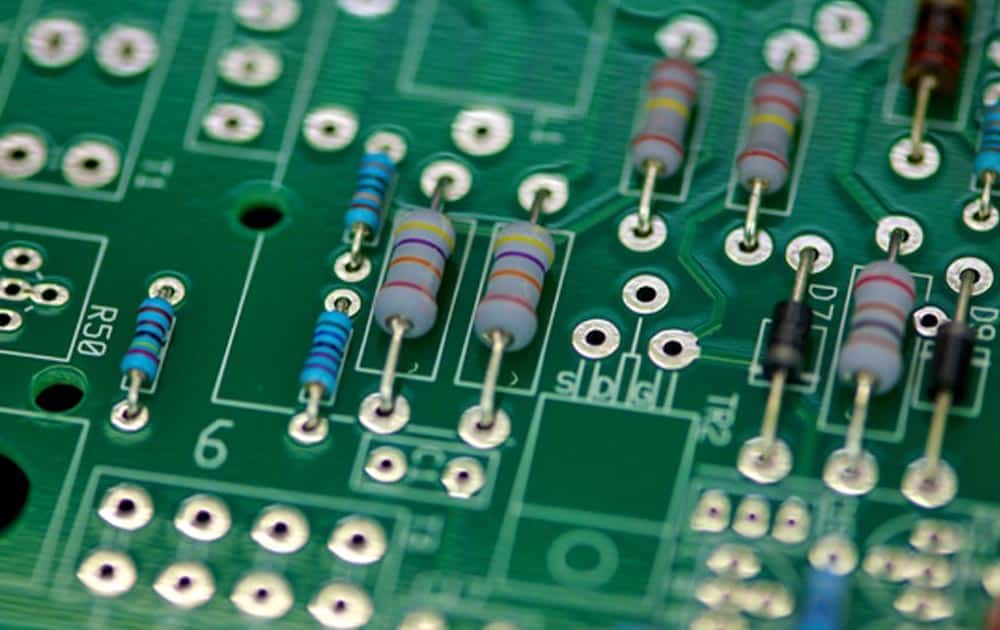

Through-hole PCB Assembly

Single and double-sided through-hole PCB assemblies.

Multi-layer boards

Cost effective assembly technique

Electrical and environmental testing

Assembled, inspected, and tested to MIL-STD and IPC specifications

Which technology is right for you?

Use the comparison chart.

What is Through-Hole PCB Assembly?

As technology rapidly advances, production methods are constantly becoming obsolete. Yet, though not used as often as before, some of these old methods thrive because the current technologies can’t outdo the benefits they offer.

Through-hole PCB assembly is one such method. Before inventing the Surface Mount Technology (SMT), all components were PCB assembled by inserting leads through the board’s component holes. Though the SMT assembly is cost-effective, more efficient, and accommodates denser boards, the through-hole PCB technology offers specific benefits that maintain its relevance.

Through-hole PCB assembly is the process of mounting electronic components with leads by inserting them through printed circuit boards (PCB) predrilled holes and soldering them to pads on the other side either manually or using automated insertion mount machines.

The solder joint has several benefits. It is the actual bond between the board and the components, and its quality equals the connection’s quality. While the solder joint appearance is insignificant, it indicates the strength of the bond.

Characteristics of PCB Assembly

Most new designs are almost exclusively SMT, but sometimes even new designs have a few through-hole components on the same PCB. These few through-hole components are usually specified for components such as connectors, push-buttons, switches, power jacks, and other types of components which are intended to have a direct interface with the user, which are often subject to high forces being applied to them by the user. As a result, through-hole custom PCBs are normally reserved for heavier or bulkier systems and integrations such as semiconductors or electrolytic capacitors in large packages.

The primary reason that through-hole PCBs are still being produced is that many companies are still working with older designs. This can typically be done so long as you aren’t running into major component obsolescence issues. However, there are usually significant cost reductions and quality improvement opportunities to update your through-hole design to an SMT design. If you’re interested in learning more about making this upgrade you can review our SMT Assembly services here.

Benefits of Through-Hole PCB Assembly

- Enhanced physical connections – through-hole PCB integrations can withstand excess environmental stress since they’re inserted through the board and not merely secured to the board’s surface like SMT assemblies.

- Easy to prototype – besides being very reliable, you can swap out through-hole connections easily.

- High heat resistance – besides their durability in acute collisions and accelerations, through-hole PCB high heat resistance makes them ideal for aerospace and military products.

- Better power-handling capacity – through-hole technology creates a strong connection between the chip on board and components that undergo high voltage, mechanical stress, and high power, including electrolytic capacitors and transformers.

SURFACE MOUNT

SURFACE MOUNT

SMT provides excellent space utilization and a very high degree of circuit reliability.

- LEARN MORE

THROUGH-HOLE PCB

THROUGH-HOLE PCB

Our through-hole PCB assembly procedure can handle both leaded and lead-free (RoHs) applications.

- LEARN MORE

HYBRID THICK FILM

HYBRID THICK FILM

A Hybrid circuit performs all or part of an electronic function by combining and interconnecting...

- LEARN MORE

CHIP ON-BOARD

CHIP ON-BOARD

When design parameters cannot be met by traditional assembly techniques, Chip-On-Board (COB)...

- LEARN MORE

MULTI-CHIP MODULE

MULTI-CHIP MODULE

MCM has the same basic construction as Chip-On-Board but with some significant differences.

- LEARN MORE

BOX BUILD ASSEMBLY

BOX BUILD ASSEMBLY

Box build assembly consists of all the remaining assembly processes required to integrate...

- LEARN MORE

LINKS

CONTACT US

103 Grant Street

Aurora, NE 68818

Phone: 402-694-6111

Toll-Free: 800-260-6287

Fax: 402-694-6180